Folding is a key part of the services Dero offer, whether it is a laser fold bracket or items incorporated within a fabrication. High accuracy folding is achieved by investment in four key areas.

- Skilled People

- Investment in the latest machines

- Investment in high quality tooling

- Investment in training

Folding

DERO FABRICATION LIMITED

Dero's Machines

Dero Fabrication Ltd, Unit 67, Blackpole Trading Estate West, Worcester, WR3 8TJ

www.dero.co.uk sales@dero.co.uk

Traditional skills, complemented by new technology.

©2007 - 2020 Dero Fabrication Limited All Rights Reserved

Three Amada's HFE-M2 3 meter Press Brakes

- HFE-M2 1703 170 Tonne

- HFE-M2 1003 100 Tonne

- HFE-M2 1703 170 Tonne

All three machines boast an impressive 8 CNC controlled axis, tapering back gauge and flexible finger positioning, all controlled using Amada's interactive AB touch screen control. These machines combined with continuous investment in tooling enables even the most complex jobs to be undertaken.

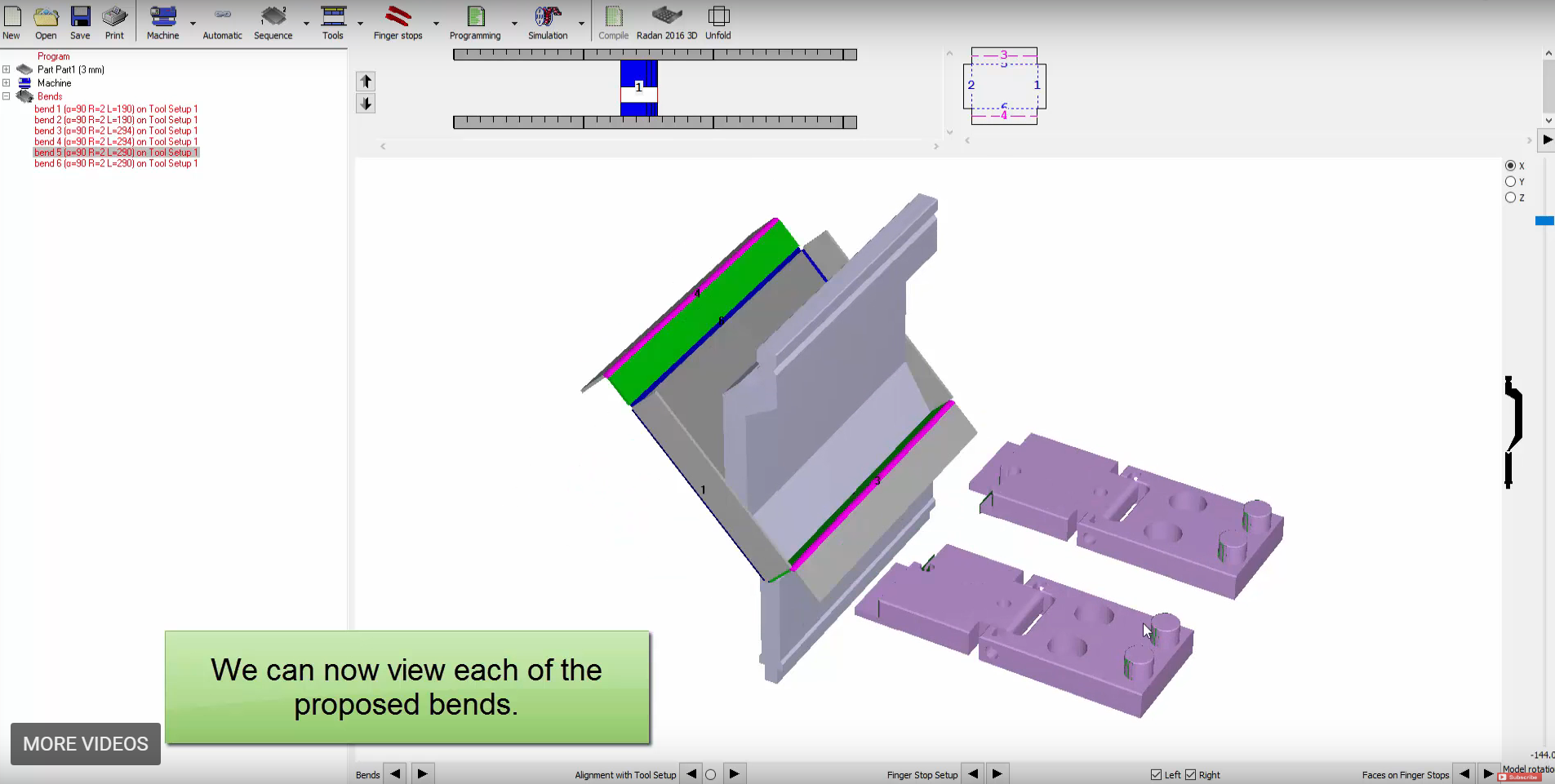

Software - Radan Radbend

Radbend is an offline programming simulation solutions for our press brake, it links and integrates with our existing Radan software to enable smooth and issue free programming.

We can now laser cut flat blanks with the confidence that the finished part will meet the customers requirements. Radbed will select the best bend sequence, tools and machine setting to enable the part to be successfully folded, limiting errors on the machine itself.

Radbend will ensure our press brakes are used to their full potential; folding parts in the past we thought to be impossible, Radbed will also guide us with investments in new tooling; ensuring we stay up to date with developments in tool design.